Date

10.02.2026

Bulgarian Church: Digital Craft & Sacred Geometry

Introduction

Contemporary architecture often demands a synthesis of daring conceptual design and rigorous constructibility. Our involvement in the conversion of an existing mews property into a new space for the Bulgarian Orthodox Church (St John of Rila) in South Kensington, London exemplifies how Patalab’s expertise in computational design and digital fabrication acts as the critical bridge between ambitious conceptual design and on-site constructibility.

Tasked with helping the contractor realise a geometrically ambitious interior within a converted mews property, Patalab utilised advanced modelling workflows to rationalise complex forms into buildable realities. This case study explores how we optimised a sophisticated “forced perspective” design into a materially-efficient kit-of-parts for rapid, precise assembly.

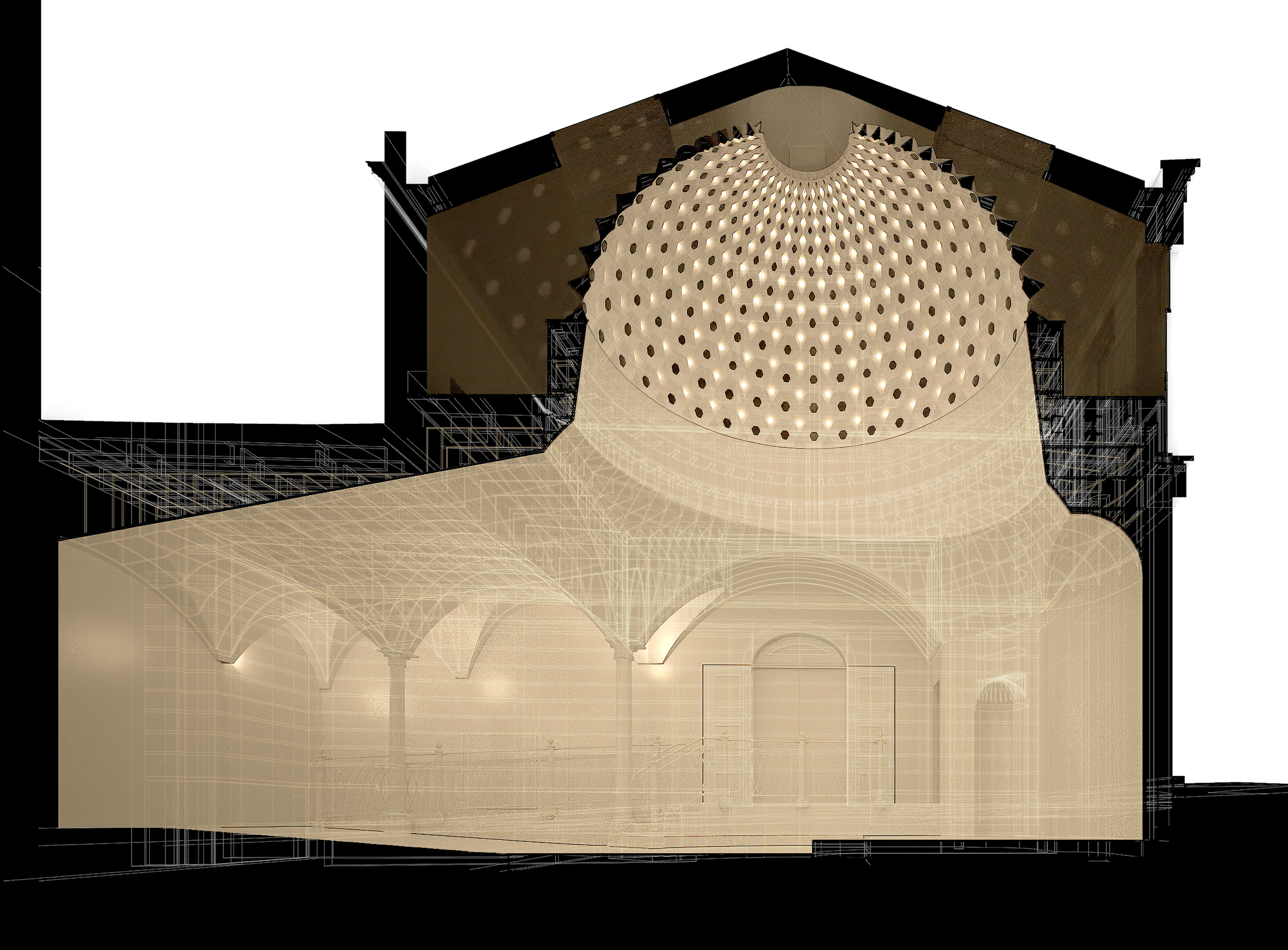

Long perspective section with skeletal techtonic overlay

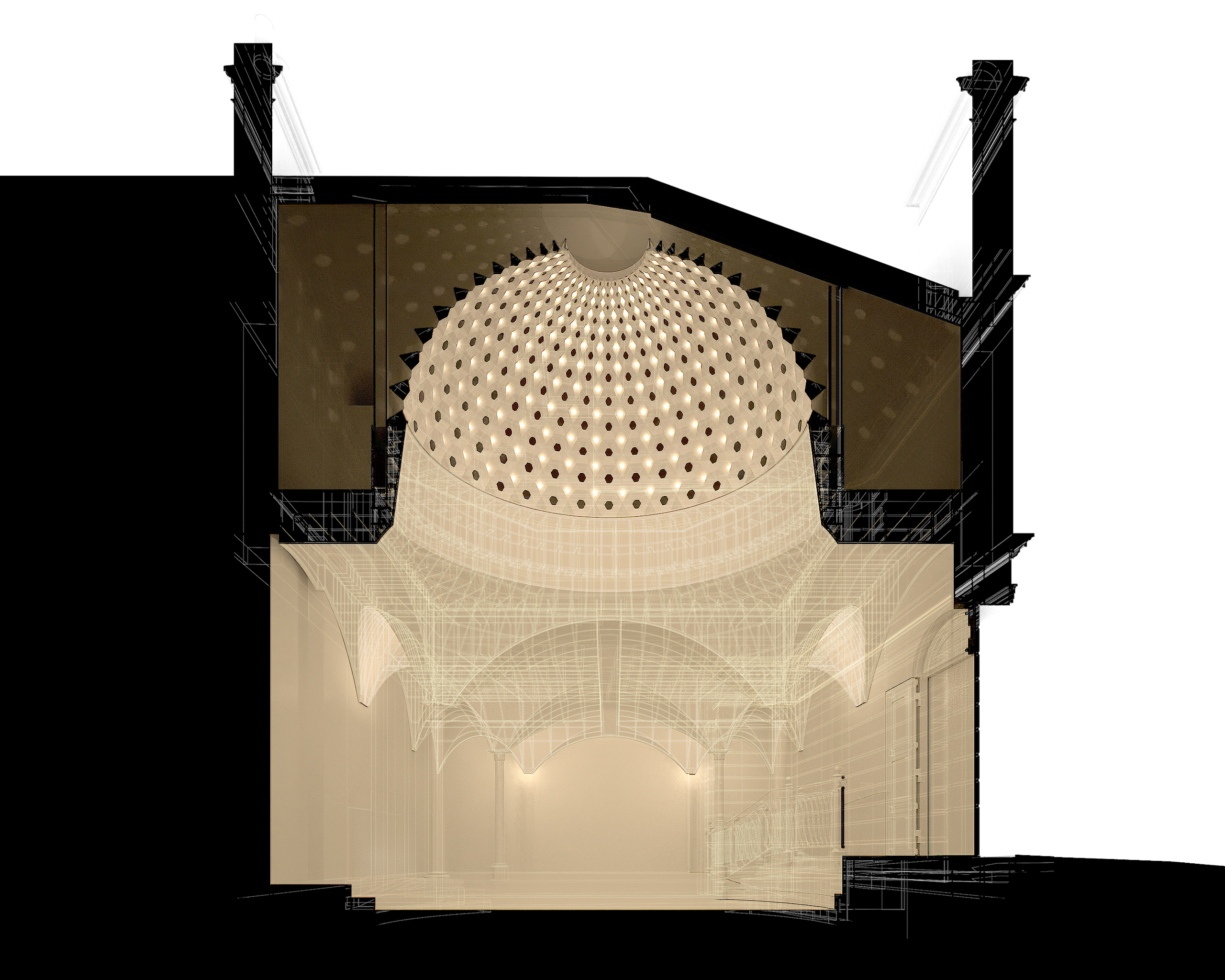

Short perspective section with skeletal techtonic overlay

The Challenge: Engineering Perception

The site—a constrained mews property—presented extremely tight spatial tolerances. Inspired by spectacular Baroque works such as Francesco Borromini’s (1599-1667) 16th century Palazzo Spada, the original design concept by Archetypes Design ingeniously adopted a principle of forced perspective to counteract the limited space. By creating a series of intersected vaulted ceilings that gradually decrease in scale, combined with a sloping floor, the design manipulates visual perception to create a sense of liturgical depth far greater than reality.

While visually compelling, this geometry presented a formidable challenge for traditional construction methods. The ceiling comprised a complex, intersected vaulted structure of varying scales, transitioning into a feature dome via a double-curved penditive and conical drum geometries. Realising this manually on-site would have been prohibitively time-consuming, costly, and prone to significant inaccuracies.

Phase 1: Digital Twin and Geometric Rationalisation

Our process began by establishing a rigorous digital foundation with high-fidelity 3D model site surveys to map the existing constraints. Using Rhino and Archicad, we fully remodelled the interior, coordinating the proposed complex geometry against the existing structure and mechanical services.

Working closely with the main contractor, Pro Construction, and the specialist joinery team at Orange Tree Joinery, we were able to refine the geometry not only for the forced-perspective perception, but also for manufacturing and assembly. This collaborative optimisation phase was critical in accounting for construction build-ups, defining material limitations, and maximising material efficiency. The resultant, highly detailed and accurate Digital Twin allowed us to simulate the build before a single piece of timber was cut.

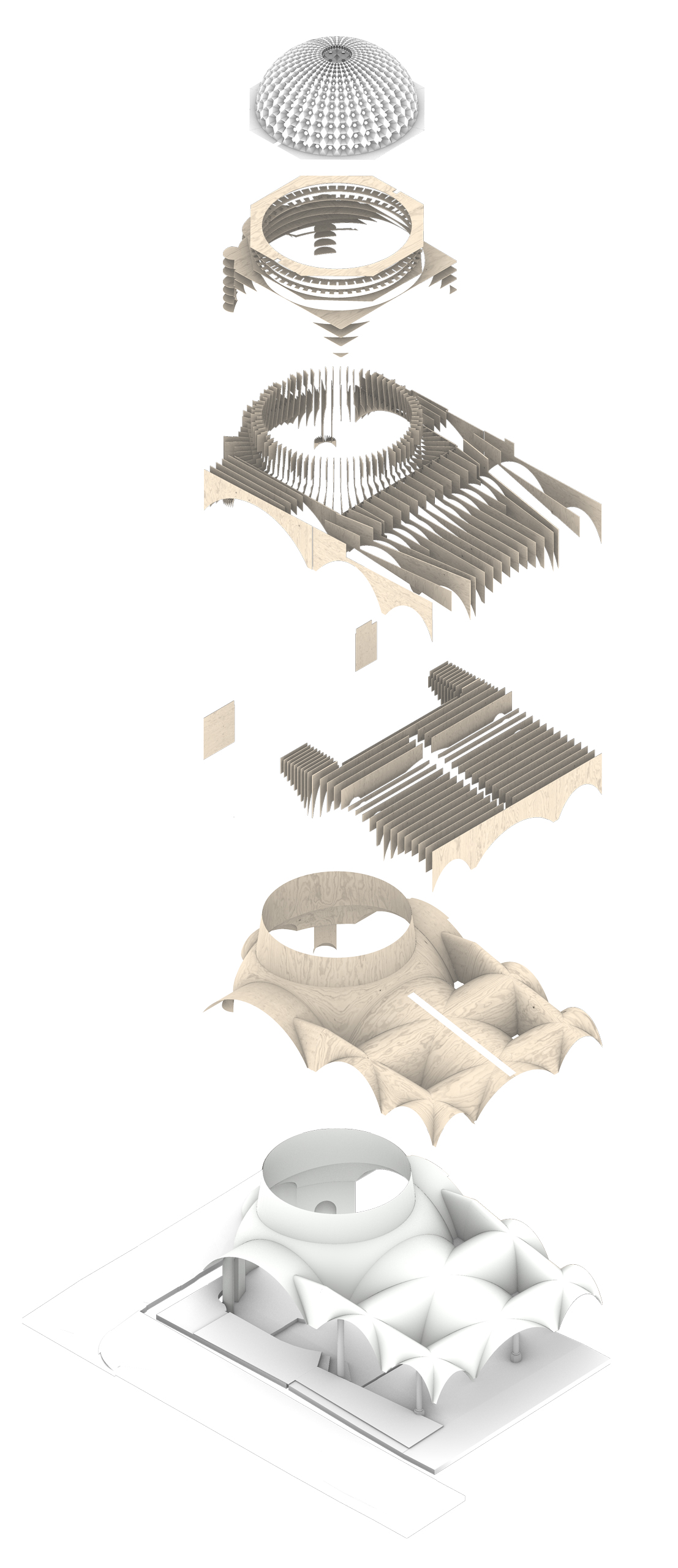

Techtonic animation and placement of forced perspective geometry within the existing mews structure

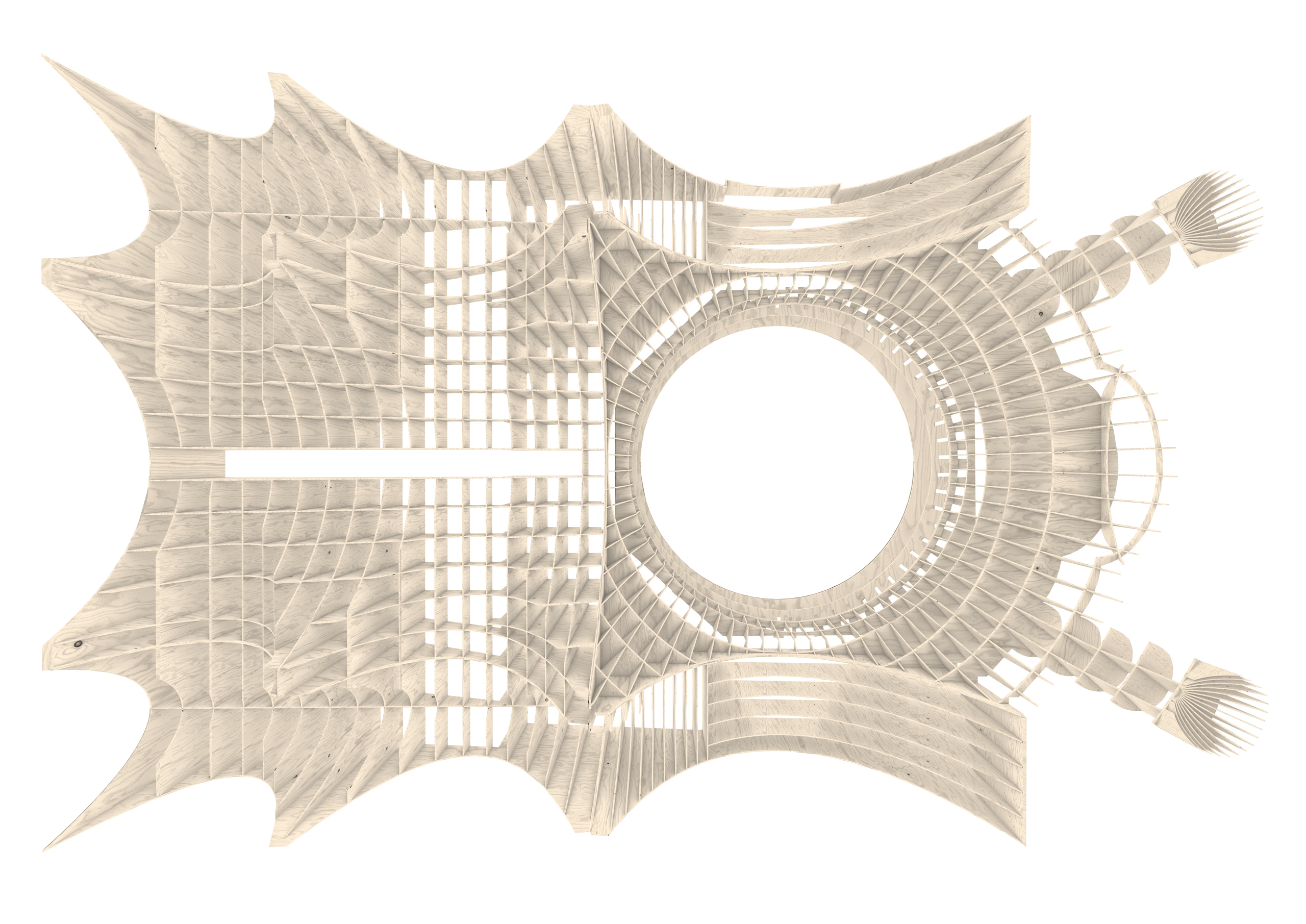

Reflective ceiling perspective plan of waffle structure

Exploded techtonic diagram of parametric waffle, aeroply and dome structures

Phase 2: The Solution - A Parametric Waffle & Aeroply Structure

To translate the continuous curves of the ceiling into a structure that could be manufactured efficiently, we developed a lightweight waffle structure system.

1. Rationalisation:

We extracted the desired ceiling surface from the digital model and sliced it into a grid of interlocking ribs within the size limits of standard plywood sheets and safe handling on site.

2. Optimisation:

The resulting structure consisted of approximately 230 unique sections. Through computational analysis, we reduced unique instances where possible and algorithmic packing scripts minimise material waste and fabrication time.

3. Unrolled Curvature:

Utilising the softwares capability of flattening complex curves surfaces much like sewing patterns, the refined geometry could then be translated into 3D reality utilising 2D Aeroply templates, minimising material waste compared with alternative methods.

4. CNC Fabrication:

Patalab extracted flattened, precisely labelled fabrication files directly from the 3D environment for the fabricator’s to finally process through their CNC (Computer Numerical Control) machines.

5. Site Assembly:

The prefabricated kit-of-parts is then efficiently assembled on site in manageable waffle structure sub-sections, with the Aeroply sheets then tying everything together and forming a robust and geometrically accurate base to receive the final finish.

This workflow shifted the complexity away from the construction site and into the digital domain. Instead of weeks of manual templating, cutting, and shimming on site, pre-fabricated interlocking sections were assembled in a matter of days. The inherent precision of the CNC-cut joints created a self-jigging structure that ensured perfect alignment, meeting the project’s tight tolerances.

Waffle and aeroply structures assembly on site

Waffle and aeroply structures assembly on site

Phase 3: A Hybrid of Digital Craft and Traditional Finish

Once the digitally fabricated skeleton was installed, it required a substrate to receive the final finish. We further leveraged the 3D model to generate flattened cutting patterns for flexible aeroply sheets. These were nested efficiently and cut via CNC, allowing the site team to skin the complex curves rapidly without complex, error-prone manual measurements or materially consumptive alternative methods.

This high-precision substrate provided the ideal canvas for a traditional finish. A fibre base layer followed by multiple coats of slow-curing lime render to create the final surface. The project thus represents a synthesis of eras: the hidden precision of algorithmic geometry supporting the visible, organic warmth of hand-crafted plaster.

Aeroply sheet geometry in plan view

Aeroply sheets unrolled from 3D model, ready for the contractor to easily install on site

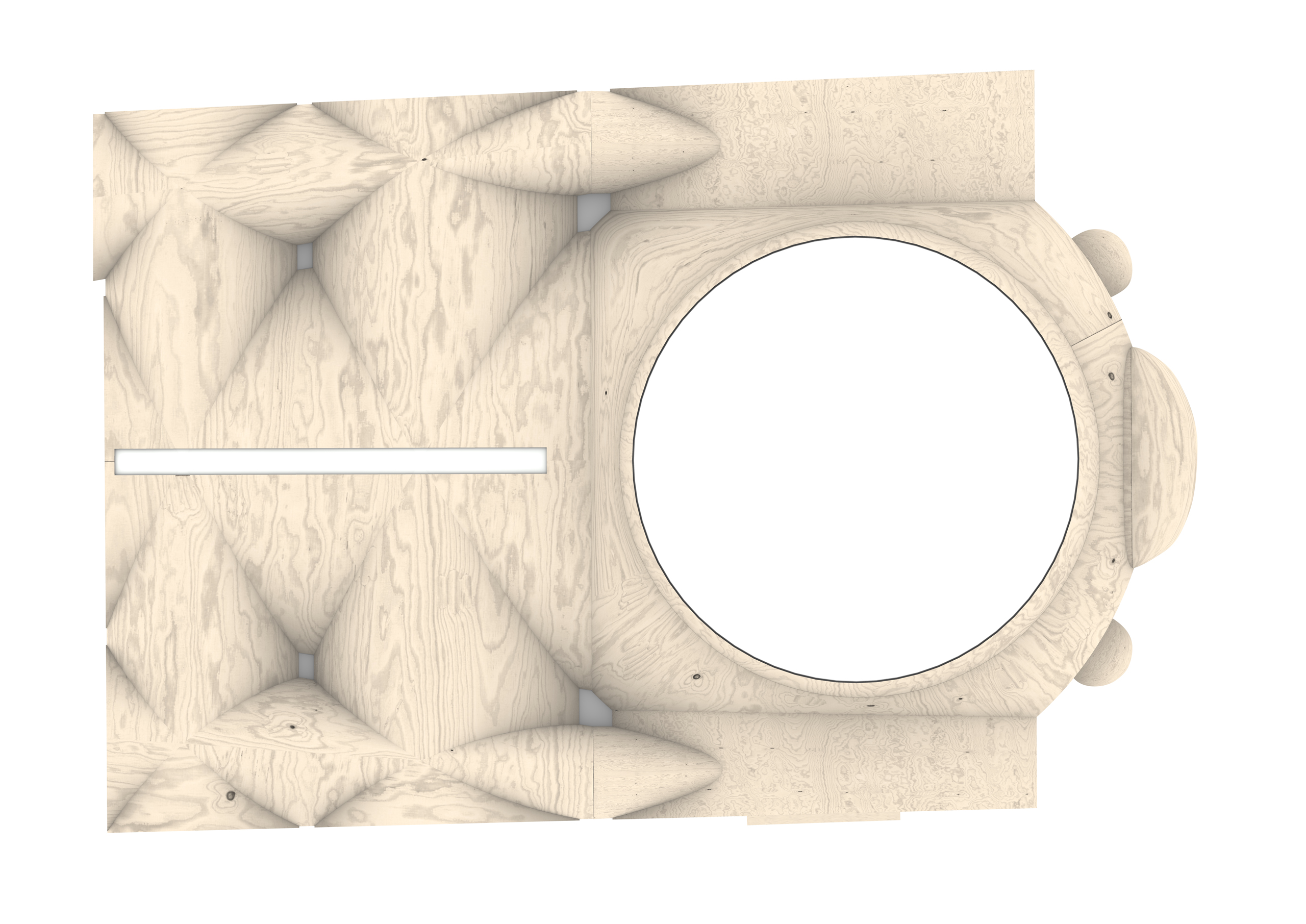

Reflective ceiling perspective plan visualisation of dome, transitioning from double-curved penditive and conical drum geometries

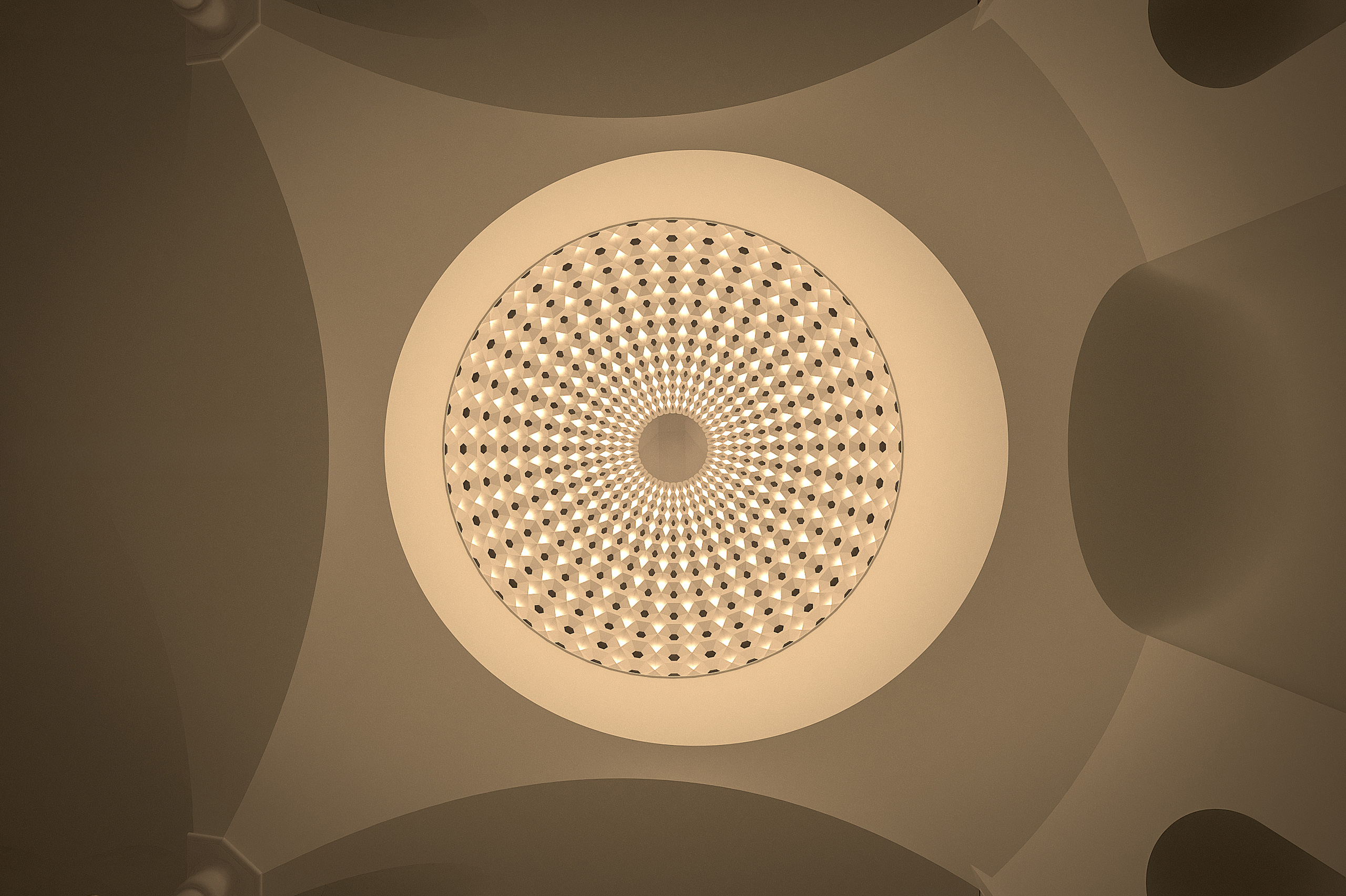

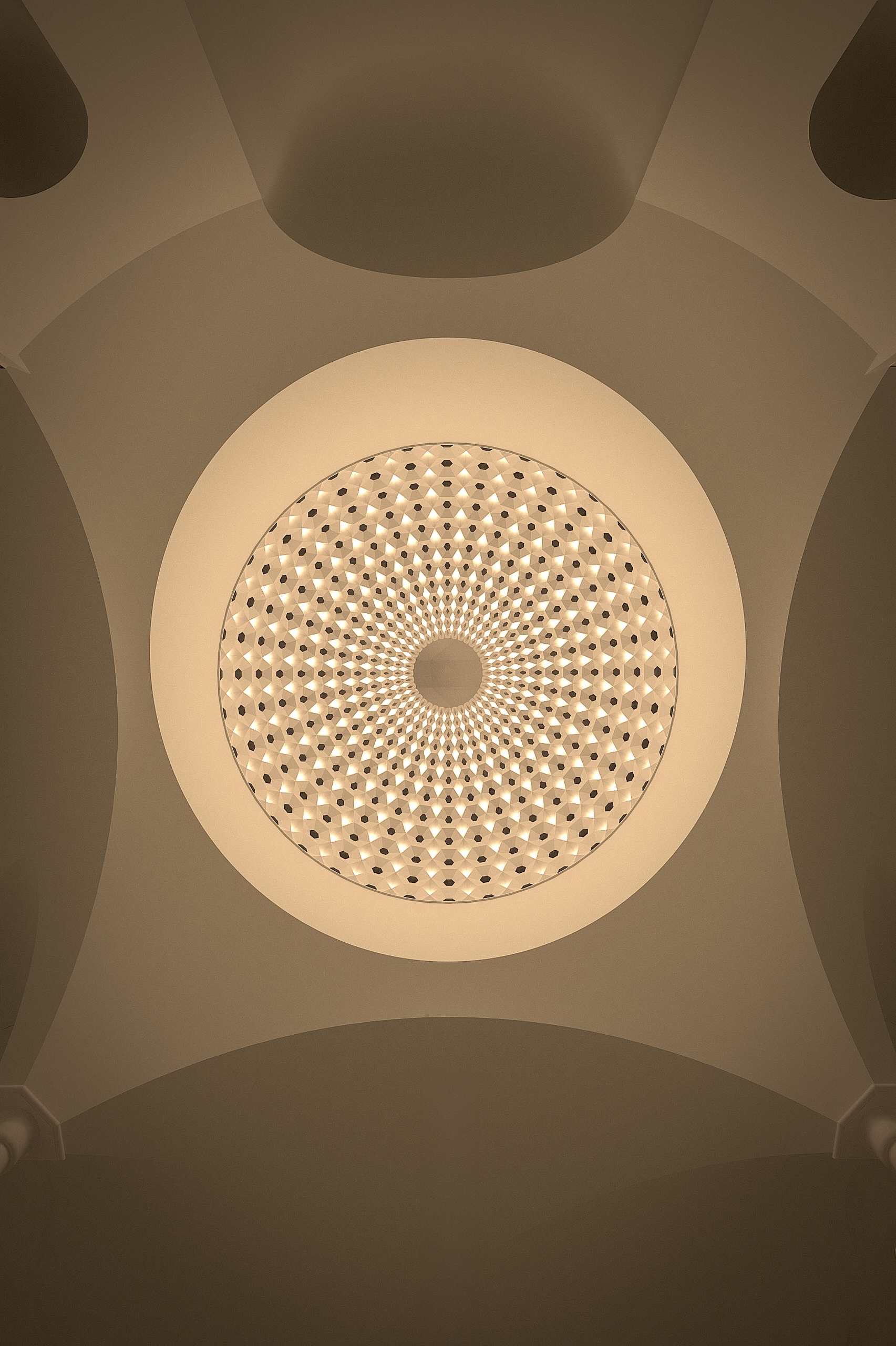

The Crown: A 3D Printed Fractal Dome

The geometry culminates in a feature dome that filters natural and artificial light. For this element, traditional timber framing was insufficient to achieve the intricate detail required, whilst sculpting would prove too costly and time-consuming.

Forming this crowning piece are 432 voussoirs – 36 repeating rows of 12 prismatic shells that gradually reduce in size to form a fractal pattern. In order to realise the pieces within the project constraints, these components were 3D printed, allowing for geometries that would be impossible to mill or cast economically. The result is a lightweight, highly detailed luminous sculpture that crowns the spiritual space.

A new space for the Bulgarian Church: completed dome and vaulted ceilings

Conclusion

The St John of Rila project demonstrates that complex geometry need not result in complex construction management. By leveraging Patalab’s expertise in digital fabrication and 3D modelling, we enabled the delivery of a high-precision architectural landmark within a tight timeframe.

We successfully transformed a logistical challenge into a seamless assembly process, proving that with the right digital tools, even the most intricate designs are achievable.